- Home »

- Videos

Videos

We don't just assemble the machines, we make them! …from pouring the castings, machining the castings, making our own turrets, to painting the machines.

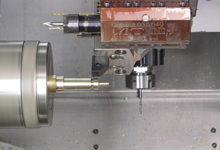

Fastest Universal Bar/Chucker on the Market - Unattended completion of complex parts in one operation

Fully adjustable gear hobbing tool completes complex parts in 1 operation, including gears and splines.

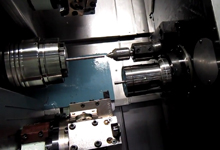

Rifle barrel machining – ideal machine for holding critical tolerances for shaft or cylinders.

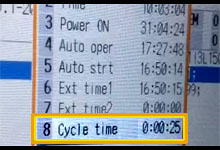

Reduced from 22.5 min. to 4.23 min. utilizing 24 live tools on the Eurotech Trofeo machine

Scary Fast 10-axis out-performs Swiss on Tough Parts: Eurotech's Superimposing Software achieves Simultaneous 3 Tools-in-the-Cut!

15 HP Main and Sub, 5 HP Live Tools, 3 Tools in the Cut, Eurotech Ladder Logic, Unmatched Accel/Deceleration Speed, Bar work, Chuck work, Tailstock work, Superimpose Sub-spindle, up to 96 Cutting Tools, 1.42" Bar capacity, 4" Chucking.

B436Y2 Rapido, utilizing the rigidity and HP of the sub spindle to polygon turn on the main spindle (1 cut including chamfers), AISI 303 stainless.

The solution is Eurotech’s Clearshift Sub-spindle combined with programmable parts gantry system, 710SLLY

Over 4,000 complex part mix is solved using Eurotech Trofeo machine and PartMaker software.

The SmartTurn has an additional tool change area to use longer tools; longer bed machine and additional ATC for extended tool length.

Truly a heavy duty turning center combined with a heavy duty machining center enables you to complete super accurate parts on all six sides in one operation

The superior design delivers extremely efficient and fast production of complex parts using live tools, Y-axis and C-axis.

Up to 16mm bar, up to 10 working axes, 2 Y-axes and 6 fully programmable (360 degree) tools working on both main and sub-spindles.

Sub-spindle, Y-axis, and a fully programmable B-axis that works on both main and sub-spindles.

Unattended completion of complex shaft parts from bar stock in a single operation

Unattended completion of complex hobbed gear parts from bar stock in a single operation

Modern State-of-the-Art Production Facilities Assure the most up-to-date High Precision CNC Technology

Get your MT tooling soiution now! Call your MT Dealer, Eurotech at 352-799-5223. www.eurotechelite.com

Eurotech Elite Single Y-axis Turret, Dual Spindle B545-SLY machining shotgun bolt in one operation

Eurotech Multipla B465-T3Y3, the Most Flexible Machining Cell, Makes the Toughest Tool Easy & Fast!

The Most Flexible Turn/Mill Machining Center on the Market - 13-axes, 2-spindles, 3 Y-axis turrets

Unbelievable number of live tools, high horsepower - made for high ROI hydraulic part machining.

Simultaneous Front and Back CNC Multi-axis Swiss-type Machining.

Complex parts complete in 1-Op!

The combination of the high precision spindles with roller and ball bearings plus the high torque and power range available at low rpm allow superb chip removal rates as well as exceptional surface finish and roundness accuracy.

Eurotech's new SwissTurn Xtreme 9-Axis Hybrid Turn/Mill Bar, One and Done Machine seen at Shot Show 2018. Machining complex gun parts in one operation.

Eurotech's new Rapido B438-SY2 Univeral CNC machining APX pistol barrel in 1-Op, utilizing Main & Sub, 2Y-axes, and live and static tooling.

Eurotech solutions that help achieve "One and Done" manufacturing on many of our customers' unique applications.

World's Most Productive CNC Chucking Machines. Over 100 models to choose from.

World's Most Productive CNC Chucking Machines. Over 100 models to choose from.

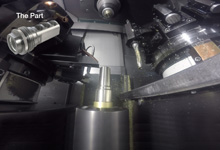

Eurotech's Rapido B438-Y2 Univeral CNC, machining Long Shaft part in 1-Op, utilizing Main, Sub, Integral Tailstock, 2Y-Axes, and Live and Static tooling.

Eurotech's Rapido B438-Y2 Univeral CNC, machining ASR Mount in 1-Op, utilizing Main, Sub, 2Y-Axes, and Live and Static tooling.

The Eurotech Rapido Connector part machined in 1-Op on the Eurotech Elite B438-Y2 hi-speed precision universal CNC turn/mill center.